FMS uses quality procedures which are operated to meet or exceed the requirements of ISO 17025.

Our test and inspection reports are documented in detailed, easy to read reports to meet our customer’s needs.

Customer satisfaction is the primary focus of our quality management system.

All tests are performed against the highest possible standards to ensure credibility and impartiality of test results.

Our customers know they can rely on us for quality service in a timely manner and for a reasonable price.

We have an in-house NDT laboratory and a

team of field technicians to help assist you with your

non-destructive testing needs. All of our NDT technicians are

qualified to a minimum ASNT Level II qualification in accordance

with ASNT SNT-TC-1A and our in-house procedures.

Visual inspection is one of the most powerful means of non-destructive testing.

FMS materials testing laboratory contains light meters, magnifiers, microscopes, weld gauges, and many other precision type measuring devices to carry out accurate and detailed visual inspections.

Magnetic Particle Testing is a non-destructive test method for detecting surface and sub-surface discontinuities in ferromagnetic materials.

At FMS, we have a stationary wet fluorescent horizontal bench unit including a de-magnetization unit and high intensity black lights for testing batch materials such as threaded fasteners or aerospace parts. We also have portable field equipment so we can come to your site when needed.

Liquid Penetrant Testing is a non-destructive testing method used for detecting discontinuities that are open to the surface of non-porous materials.

At FMS, we have specialized stationary equipment with high intensity black lights for performing fluorescent penetrant inspections at different sensitivity levels on batch materials such as threaded fasteners and aerospace parts. We also have portable fluorescent and visible dye materials for field testing and testing of weldments.

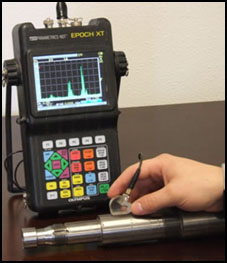

Ultrasonic Testing is a method in which beams of high frequency sound waves are introduced into the material being tested and are used to detect surface and sub-surface flaws.

At FMS, we use state of the art ultrasonic equipment with transducers suitable for taking thickness measurements and performing shear wave flaw detection.

Copyright 2017.Faircloth Metallurgical Services, LLC . All Rights Reserved.